aggregate impact test procedure pdf|aggregate impact value aiv test : dealer 3.1.1 Definition and test method—Grading refers to the distribution of particle sizes present in an aggregate. The grading is determined in accordance with ASTM C 136, “Sieve or Screen . Reading [Shoot The Moon (Fuetakishi)] Batsu Game de Yankee Onna ni Kokuttemita 3 [English] [HappyCoffeeStudios] [Digital]

{plog:ftitle_list}

webNo entanto, se quisermos iniciar uma conversa com um cuidador ou babá, precisaremos ser assinantes do serviço premium. Requisitos e informação adicional: Requer como .

The aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact, which in some aggregates differs from its resistance to a slow compressive .3.1.1 Definition and test method—Grading refers to the distribution of particle sizes present in an aggregate. The grading is determined in accordance with ASTM C 136, “Sieve or Screen .The aggregate impact value is a measure of resistance to sudden impact or shock, which may differ from its resistance to gradually applied compressive load. Procedure of Aggregate .AGGREGATES IMPACT VALUE OF SOFT COARSE AGGREGATES. ( Fourth Reprint AUGUST 1991 )

The aggregate impact value gives a relative measure of the resistance of the aggregate to sudden shock or impact. The particular purpose which an aggregate is meant to serve .INTRODUCTION. This manual is intended to supplement, not in any way to supersede, the various ASTM test methods for sampling and testing aggregate and freshly mixed and .This manual presents the standardized test procedures to carry out the tests on aggregates, tests on bituminous materials, and Marshall Mix Design test, California Bearing Ratio (CBR) .1.1 This standard (Part IV) covers the following tests for aggregates for concrete : Determination of Aggregate Crushing \‘alue, Determination of the 10 percent Fines Value, Determination of .

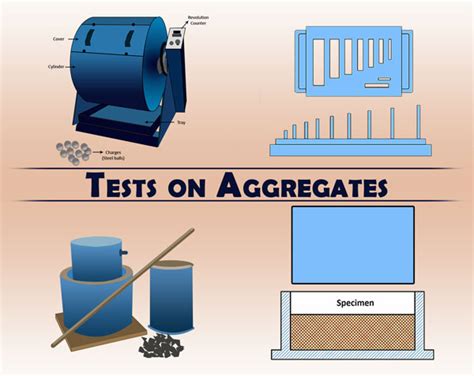

8.3 Aggregate tests. In order to decide the suitability of the aggregate for use in pavement construction, following tests are carried out: Crushing test. Abrasion test. Impact test. .compressive load. With aggregate of aggregate impact value (AIV) higher than 30 the result may be anomalous. Also aggregate sizes larger than 14 mm are not appropriate to the aggregate impact test. The standard aggregate impact test shall be made on aggregate passing a 14. mm BS test sieve and retained on a 10.0 mm BS test sieve. If required .

impact testing machine for aggregates

This document describes a test method for determining the aggregate impact value (AIV) of aggregates, which provides a measure of their resistance to sudden shock or impact. The test involves compacting aggregate samples in .4. procedure. The test sample shall consist of aggregate the whole of which passes a 12.5 mm IS Sieve and is retained on a 10 mm IS Sieve. The aggregate comprising the test sample shall be dried in an oven for a period of four hours at a temperature of 100 to 110°C and cooled.The method is not suitable for testing aggregates with an aggregate crushing value higher than 30, and in such cases the method for ten per cent fines value described in BS 812-111 is applicable. A test specimen is compacted in a standardized manner into a steel cylinder fitted with a freely moving plunger.California Test 201 – Soil and Aggregate Sample Preparation. California Test 202 – Sieve Analysis of Fine and Coarse Aggregates. AASHTO M 92 – Wire-Cloth Sieves for Testing Purposes . AASHTO T 96 – Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM C 131 – Standard Test .

Sieve Analysis Test Procedure and Calculation. Construction Materials. Determination of Standard Consistency of Cement. Geotechnical. Plate Load Test – Safe Bearing Capacity of Soil . Aggregate Impact Value Test. Construction. 390+ IS Codes List – Indian Standard Codes in Civil Engineering. Construction. Civil Engineering Final Year . Impact Test Fig-3 Impact Test Setup. The aggregate impact test is carried out to evaluate the resistance to impact of aggregates. Aggregates passing 12.5 mm sieve and retained on 10 mm sieve is filled in a cylindrical steel cup of internal dia 10.2 mm and depth 5 cm which is attached to a metal base of impact testing machine.

The procedure of the impact value test includes the following series of steps: 1. The aggregate samples of size 10mm to 12.5mm (passing through 12.5mm sieve and retained on 10mm sieve) are first taken and oven-dried at a temperature ranging from 100 degrees Celsius to 110 degrees Celsius for about four hours.Procedure 1. The material for the standard test shall consist of aggregate passing a 12.5 mm IS Sieve and retained on a 10 mm IS Sieve, and shall be thoroughly separated on these sieves before testing. 2. The aggregate shall be tested in a surface-dry condition. . Aggregate Crushing Value Test 8. Download Download PDF. Author: CC 3. PROCEDURE Procedures of ASTM C131 and C535 shall be followed, except as noted below, for the determination of degradation of coarse aggregate by abrasion and impact using the Los Angeles testing machine 4. EXCEPTIONS 4.1 SIEVES: Conforming to ASTM E11, except use 13.2 mm sieve size instead of 12.5 mm...

7.6.6 Aggregate impact value 7.6.6.1 Procedure a) Test specimens in a dry condition (i) Fix the cup firmly in position on the base of the impact machine and place the . Follow the test procedure described in 7.6.6.1(a) except that the number of blows of the hammer to which the aggregate is subjected, is the number of .To understand the role played by aggregate in the performance of concrete, it is necessary to de fine specific aggregate properties and show their effect on concrete properties. CHAPTER 3—AGGREGATE PROPERTIES AND TEST METHODS 3.1—Grading 3.1.1 Definition and test method—Grading refers to the distribution of particle sizes present in an .3.2.1.1 Test Method C143/C143M Slump of Hydraulic-Cement Concrete, or Test Method C1611/C1611M Test Method for Slump Flow of Self-Consolidating Concrete. 3.2.1.2 Test Method C173/C173M Air Content of Freshly Mixed Concrete by the Volumetric Method, or Test Method C231/C231M Air Content of Freshly Mixed Concrete by the Pressure Method.

2.1 Object - This method covers the procedure for determination of particle size distribution of fine, coarse and all-in-aggregates by sieving or screening. 2.2 Apparatus 2.2.1 Sieves - Sieves of the sizes given in Table I, conforming to IS : 460-1962 Specification for Test Sieves ( Revised) shall be used. 4 Aggregate impact value test experiment - Download as a PDF or view online for free. Aggregate impact value test experiment - Download as a PDF or view online for free . PROCEDURE • The sample was cleaned by .

aggregate test is code

The L.A. Abrasion test is a nationally recognized method for determining the quality of coarse aggregate. In this method, a specifically graded aggregate sample is placed in a revolving drum with steel charges, and rotated for 500 revolutions at a rate of 30 to 33 revolutions per minute. AASHTO, 2009) By

Download Free PDF. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine 1. . NOTE 1—A procedure for testing coarse aggregate larger .

NOTE 1-Unit weight was the previous terminology used to describe the property determined by this test method, which is mass per unit volume. 1 This test method is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.60 on Testing Fresh Concrete.Table 1: Classification of aggregate based on aggregate impact value Aggregate impact value (%) Quality of aggregate < 10 Exceptionally strong 10 – 20 Strong 20 – 30 Satisfactory for road surfacing >35 Weak for road surfacing Table 2: Maximum allowable impact values of aggregate in different types of Pavement material/ layers Sl.No Types of .ASTM C123 - Test Method for Lightweight Particles in Aggregate. Bulk Density of Slag: ASTM C29/C29M - Test Method for Bulk Density and Voids in Aggregate. Abrasion of Coarse Aggregate: 1. ASTM C131-Test Method for Resistance to Degradation of SmallSize Coarse Aggregate by abrasion and Impact in the Los Angeles Machine. 2. PDF | Crushing test and Impact test are very important to estimate strength and toughness characteristics of the road aggregate. . For this experimental procedure, 60 aggregate samples were .

Practice D 75 and reduced to test portion size in accordance with Practice C 702. 6.2 Fine Aggregate—Fine aggregate for the test shall be 6 Experience with the test method indicates that a grade of sodium sulfate desig-nated by the trade as dried powder, which may be considered as approximately anhydrous, is the most practical for use.

4. procedure. The test sample shall consist of aggregate the whole of which passes a 12.5 mm IS Sieve and is retained on a 10 mm IS Sieve. The aggregate comprising the test sample shall be dried in an oven for a period of four hours at a temperature of 100 to 110°C and cooled.(B) By Autoclave Method 30 1.5 Strength Test 35 2 Tests on Aggregates 43 2.1 Sieve Analysis 45 2.2 Water Absorption 50 2.3 Aggregate Abrasion Value 57 2.4 Aggregate Impact Value 61 2.5 Aggregate Crushing Value 65 2.6 Silt Content 70 2.7 Bulking of Sand 75 2.8 Flakiness Index and Elongation Index 77 3 Tests on Reinforcement Steel 83 3.1 Tensile .limitations before any testing is performed. A. SCOPE This test method which is a modification of AASHTO Designation T 96, is used to determine the resistance of coarse aggregate to impact in a rotating cylinder containing metallic spheres. This test is known as the Los Angeles Rattler Test. B. APPARATUS 1. Los Angeles Machine. The Los Angeles

Aggregate impact value = W1 W2 × 100 Aggregates to be used for wearing course, the impact value shouldn’t exceed 30 percent. For Mould Falling Hammer Specimen Figure 8:3: Impact test setup bituminous macadam the maximum permissible value is 35 percent. For Water bound macadam base courses the maximum permissible value defined by IRC is 40 .The average aggregate crushing value (ACV) and the aggregate impact value (AIV) obtained from the evaluations is 28.7% and 29.5% respectively and are within the acceptable standard limits. The specific gravity and water absorption gave average values of 2.60 and 0.22% respectively while the flakiness index obtained from the analysis is 26.7%.

aggregate impact value test pdf

aggregate impact value test lab report pdf

SUMMARY. REVIEWS (11) You are reading God Jangsan Tiger manga, one of the most popular manga covering in Comedy, Fantasy, Full Color, Josei, Manhwa, Romance, .

aggregate impact test procedure pdf|aggregate impact value aiv test